Conductors

Copper-bonded steel tape 3 mm

| Cat. no. | X x Y mm |

Length* m |

Material |

| C1100272(60M) | 20 x 3 | 60 | steel copper-bonded to thickness of 0.070 mm |

| C1100273(40M) | 25 x 3 | 40 | |

| C1100279(40M) | 30 x 3 | 40 |

* for special orders we supply different tape lengths

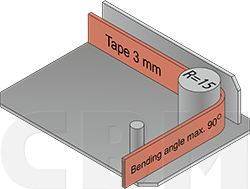

According to PN/EN 62561-2 standard, the tape may be bent at a maximum angle of 90º ± 5° and the bending radius should be equal to five times the thickness of the tape ± 1 mm.

For 3 mm tape, the bending radius should not be less than 15 mm.

The drawing presents an apparatus which enables the tape to be bent correctly.

Tinned copper-bonded steel tape 3 mm

Sale unit is kilogram, the tolerance of weight ± 5%. The tape width tolerance is ± 1 mm

| Cat. no | X x Y mm |

Length* m |

Material |

| C1100291(60M) | 20 x 3 | 60 | tinned copper-bonded steel, copper thickness min. 0.070 mm |

| C1100292(40M) | 25 x 3 | 40 | |

| C1100294(40M) | 30 x 3 | 40 |

* for special orders we supply different tape lengths

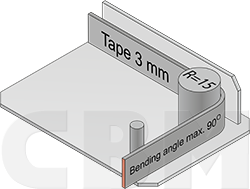

According to PN/EN 62561-2 standard, the tape may be bent at a maximum angle of 90º ± 5° and the bending radius should be equal to five times the thickness of the tape ± 1 mm.

For 3 mm tape, the bending radius should not be less than 15 mm.

The drawing presents an apparatus which enables the tape to be bent correctly.

Copper-bonded steel tape 4 mm

| Cat. no. | X x Y mm |

Length* m |

Material |

| C1100274(30M) | 25 x 4 | 30 | steel copper-bonded to thickness of 0.070 mm |

| C1100275(25M) | 30 x 4 | 25 | |

| C1100275(30M) | 30 x 4 | 30 | |

| C1100281(20M) | 40 x 4 | 20 |

* for special orders we supply different tape lengths

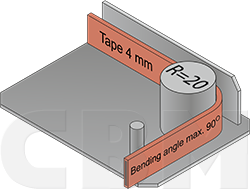

According to PN/EN 62561-2 standard, the tape may be bent at a maximum angle of 90º ± 5° and the bending radius should be equal to five times the thickness of the tape ± 1 mm.

For 4 mm tape, the bending radius should not be less than 20 mm.

The drawing presents an apparatus which enables the tape to be bent correctly.

Tinned copper-bonded steel tape 4 mm

Sale unit is kilogram, the tolerance of weight ± 5%. The tape width tolerance is ± 1 mm

| Cat. no | X x Y mm |

Length* m |

Material |

| C1100293(30M) | 25 x 4 | 30 | tinned copper-bonded steel, copper thickness min. 0.070 mm |

| C1100295(25M) | 30 x 4 | 25 | |

| C1100295(30M) | 30 x 4 | 30 | |

| C1100296(20M) | 40 x 4 | 20 |

* for special orders we supply different tape lengths

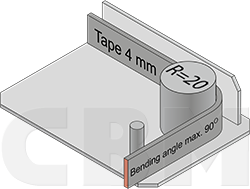

According to PN/EN 62561-2 standard, the tape may be bent at a maximum angle of 90º ± 5° and the bending radius should be equal to five times the thickness of the tape ± 1 mm.

For 4 mm tape, the bending radius should not be less than 20 mm.

The drawing presents an apparatus which enables the tape to be bent correctly.

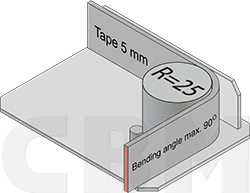

Copper-bonded steel tape 5 mm

| Cat. no. | X x Y mm |

Length* m |

Material |

| C1100283(20M) | 40 x 5 | 20 | steel copper-bonded to thickness of 0.070 mm |

* for special orders we supply different tape lengths

According to PN/EN 62561-2 standard, the tape may be bent at a maximum angle of 90º ± 5° and the bending radius should be equal to five times the thickness of the tape ± 1 mm.

For 5 mm tape, the bending radius should not be less than 25 mm.

The drawing presents an apparatus which enables the tape to be bent correctly.

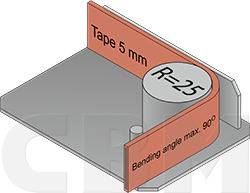

Tinned copper-bonded steel tape 5 mm

Sale unit is kilogram, the tolerance of weight ± 5%. The tape width tolerance is ± 1 mm

| Cat. no | X x Y mm |

Length* m |

Material |

| C1100284(20M) | 40 x 5 | 20 | tinned copper-bonded steel, copper thickness min. 0.070 mm |

* for special orders we supply different tape lengths

According to PN/EN 62561-2 standard, the tape may be bent at a maximum angle of 90º ± 5° and the bending radius should be equal to five times the thickness of the tape ± 1 mm.

For 5 mm tape, the bending radius should not be less than 25 mm.

The drawing presents an apparatus which enables the tape to be bent correctly.

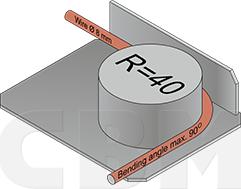

Copper-bonded steel wire Ø 8 mm

Sale unit is kilogram, the tolerance of weight ± 5%

| Cat. no. | Diameter mm |

Standard coil size m |

Material |

| C1110249 | Ø 8 | acc. to order | steel copper-bonded to thickness of 0.070 mm |

| C1110249(20M) | Ø 8 | 20 | |

| C1110249(60M) | Ø 8 | 60 | |

| C1110249(80M) | Ø 8 | 80 | |

| C1110249C250 | Ø 8 | acc. to order | steel copper-bonded to thickness of 0,250 mm |

According to PN/EN62561-2 standard, the wire may be bent at a maximum angle of 90º ± 5° and the bending radius should be equal to five times the thickness of the wire ± 1 mm.

For 8 mm wire, the bending radius should not be less than 40 mm.

The drawing presents an apparatus which enables the wire to be bent correctly.

Tinned copper-bonded steel wire Ø 8 mm

Steel wire is molecularly bonded in electrolytic process with copper of thickness 0.070 mm and tin. Tin protective coating increases the corrosion resistance in every kind of agresive soil and also protects against theft.

Sale unit is kilogram, the tolerance of weight ± 5%

| Cat. no. | Diameter mm |

Standard coil size m |

Material |

| C1110280 | Ø 8 | acc. to order | tinned copper-bonded steel, copper thickness min. 0.070 mm |

| C1110280(20M) | Ø 8 | 20 | |

| C1110280(60M) | Ø 8 | 60 | |

| C1110280(80M) | Ø 8 | 80 |

According to PN/EN 62561-2 standard, the wire may be bent at a maximum angle of 90º ± 5° and the bending radius should be equal to five times the thickness of the wire ± 1 mm.

For 8 mm wire, the bending radius should not be less than 40 mm.

The drawing presents an apparatus which enables the wire to be bent correctly.

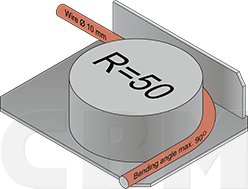

Copper-bonded steel wire Ø 10 mm

Sale unit is kilogram, the tolerance of weight ± 5%

| Cat. no. | Diameter mm |

Standard coil size m |

Material |

| C1110250 | Ø 10 | acc. to order | steel copper-bonded to thickness of 0.070 mm |

| C1110250(20M) | Ø 10 | 20 | |

| C1110250(50M) | Ø 10 | 50 |

According to PN/EN 62561-2 standard, the wire may be bent at a maximum angle of 90º ± 5° and the bending radius should be equal to five times the thickness of the wire ± 1 mm.

For 10 mm wire, the bending radius should not be less than 50 mm.

The drawing presents an apparatus which enables the wire to be bent correctly.

Tinned copper-bonded steel wire Ø 10 mm

Steel wire is molecularly bonded in electrolytic process with copper of thickness 0.070 mm and tin. Tin protective coating increases the corrosion resistance in every kind of agresive soil and also protects against theft.

Sale unit is kilogram, the tolerance of weight ± 5%

| Cat. no. | Diameter mm |

Standard coil size m |

Material |

| C1110281 | Ø 10 | acc. to order | tinned copper-bonded steel, copper thickness min. 0.070 mm |

| C1110281(20M) | Ø 10 | 20 | |

| C1110281(50M) | Ø 10 | 50 |

According to PN/EN 62561-2 standard, the wire may be bent at a maximum angle of 90º ± 5° and the bending radius should be equal to five times the thickness of the wire ± 1 mm.

For 10 mm wire, the bending radius should not be less than 50 mm.

The drawing presents an apparatus which enables the wire to be bent correctly.